Pick-and-Place Automation with AMR Mobility

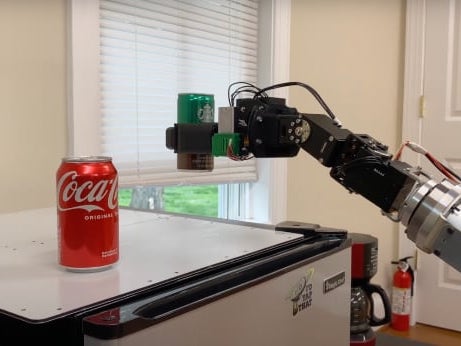

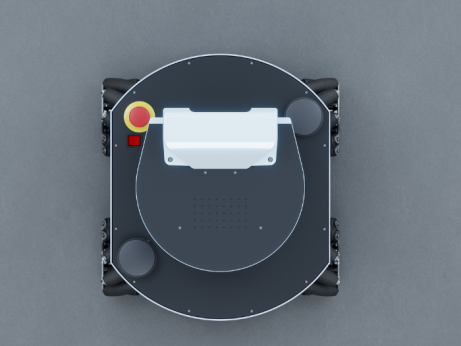

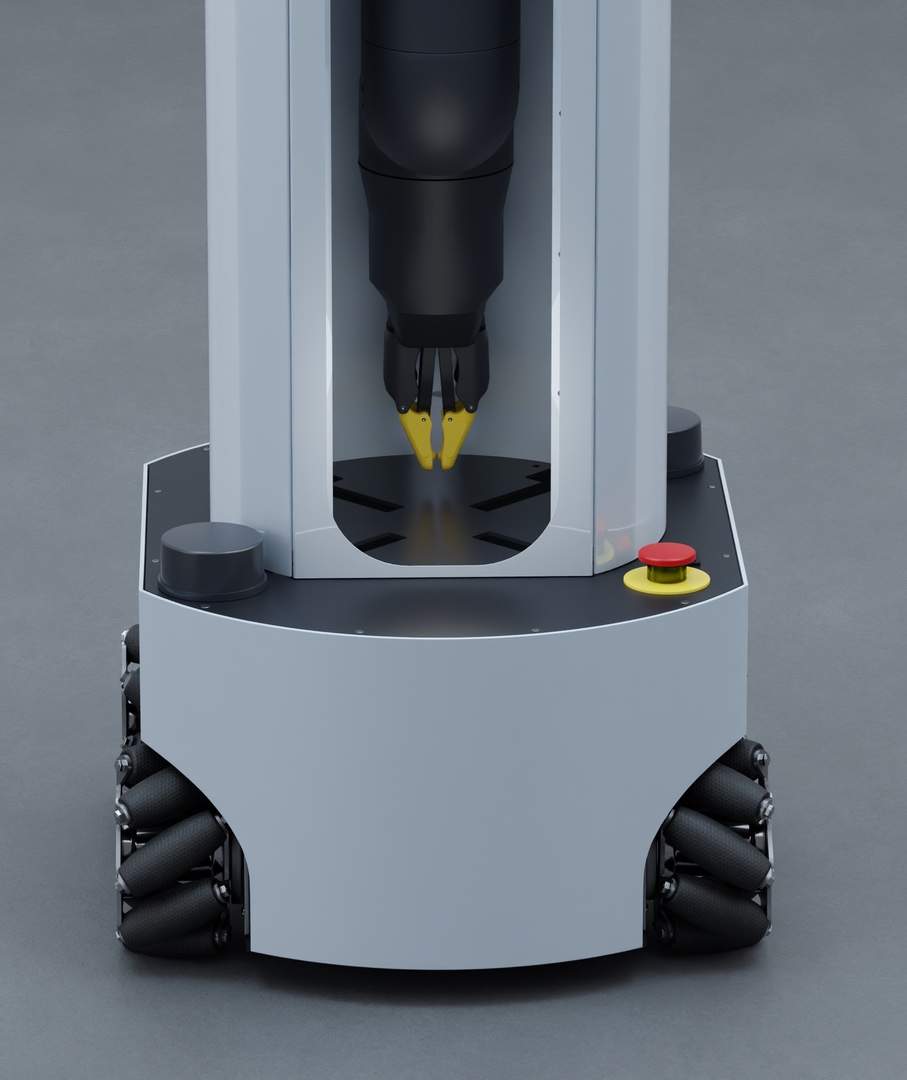

The Model R2 AMR combines the precision handling of a robotic arm with the freedom and flexibility of an autonomous robot base for unmatched autonomous mobility, object manipulation, and adaptable integration, all powered by Q.AI intelligence.

Unrestricted Reach without Repositioning

Standard pick-and-place robots are limited by their fixed robotic arms, often requiring manual repositioning that counters their proposed efficiency.

Model R2 is different:

- Serves multiple workstations without manual repositioning

- Maximizes robot uptime with direct point-to-point movement

- Enables material handling automation in every corner of your facility

Limitless Application for Endless Workflow Flexibility

For custom workflows – adaptability is key. Machines designed for single, specific tasks may work in the short-term, but limit scalability as your workflows evolve.

Model R2 provides ultimate automation flexibility:

- Custom task programming via no-code interface

- Painless deployment and open integration

- Modular design for workflow-tailored modification

- Ever-improving performance via Q.AI machine learning

Complete Automation with Full System Integration

The Model R2 bridges the gap between automation islands to connect your existing equipment and create a fully automated workflow.

- Transport materials, parts, WIPs between isolated stations

- Identify objects to load/unload machines without human intervention

- Pair with the C2 to automate facility-wide picking and delivery

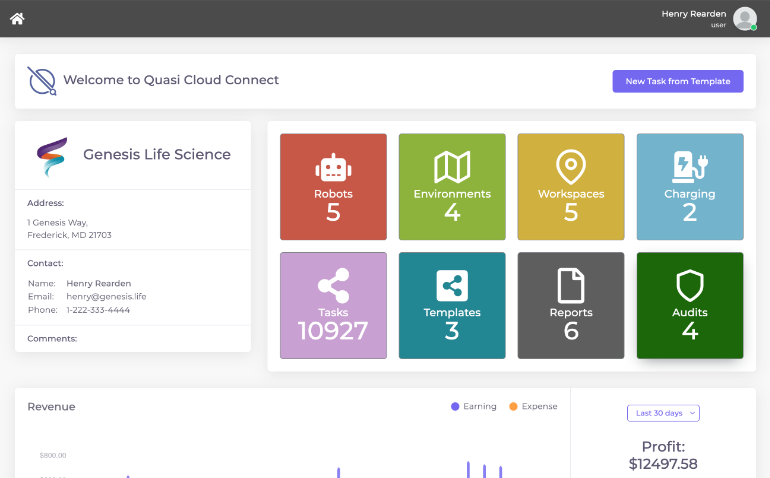

- Centralized fleet management & data insight via Cloud Connect® interface

Additional Sensors on Quasi

Autonomous Mobile Robots AMRs

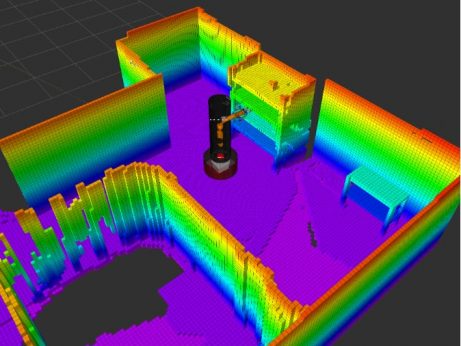

Each Model R2 comes equipped with a variety of additional sensors, for continuous monitoring of internal and external environmental states of the automated mobile robots.

Standard configuration of Quasi Automated Mobile Vehicles include:

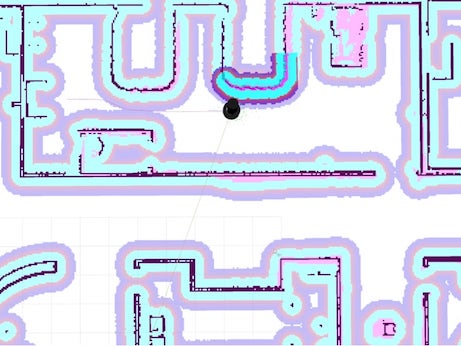

All sensor data is processed by Q.AI and uploaded for display in Cloud Connect. Historical data is kept in a permanent, read-only Audit Log alongside the timestamp and exact R2 robot position in the Environment map.

Integrated AI and Machine Learning Functionality within each Model R2 AMR Robot

Q.AI Intelligence

AI-Driven Capabilities & Integrated Automation

The Q.AI Intelligence bundle of proprietary algorithms transforms raw sensor data and hardware machinery into real-time decision making. It enables continuous learning, adaptation, and optimization, transforming the Model R2 from a mere machine into an intelligent, ever-evolving collaborator for your facility automation goals.