Mobile Robot Supply Delivery

Applications by Industry

Discover how the Model C2 addresses material transport challenges across a range of industries:

Life Science

Healthcare

Warehousing

Education

Hospitality and Others

Autonomous Supply Delivery Robots

in Life Science

Industry Challenges

Increasing Testing Demands for Biomedical Lab Technicians

73 %

labs face moderate or severe understaffing

67 %

of staff cite burnout as main reason for quitting

7 of 10

diagnoses rely on lab test result

14 billion

samples processed per year by labs in US

Workforce crisis, time-sensitive testing, and manual processes create a challenging lab environment with high turnover, financial burden, and compromised research.

The Model C2 Effect

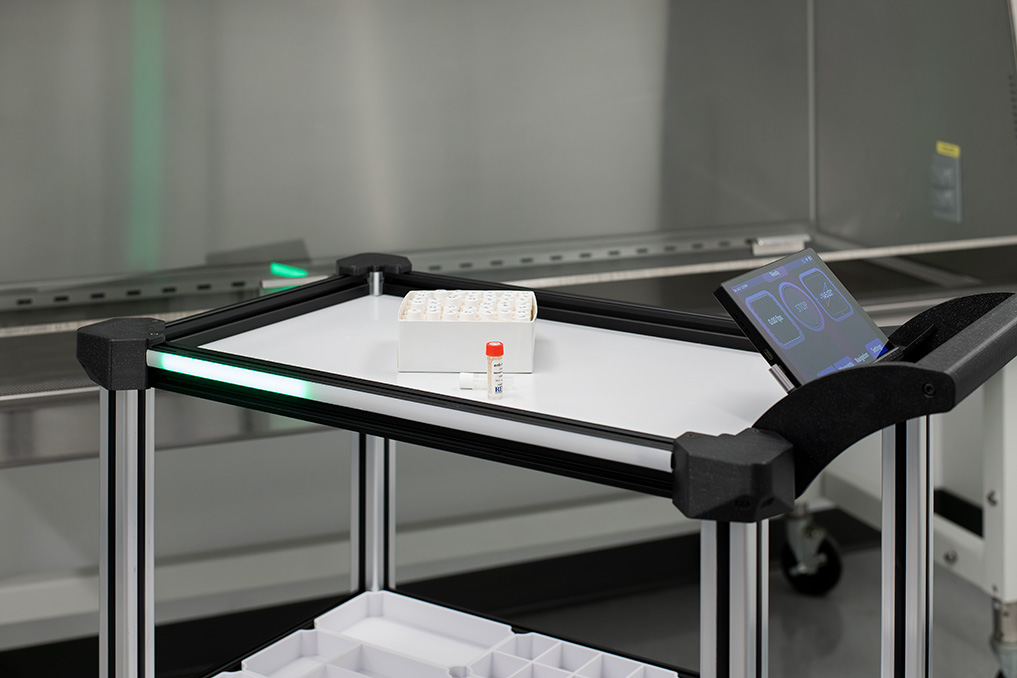

Optimized Autonomous Laboratory Supply Delivery

Better Staff Performance, Driven by Autonomous Supply Delivery

-

Keep Team Focus on Research Innovation

Redirect team focus toward critical research analysis, not trivial supply retrieval.

-

Enhance Workplace Safety

Reduce the risk of accidents and injuries associated with manual handling and transport of materials.

-

Retain & Empower Top Talent:

Create a better staff environment with less manual strain, disruption, and turn-over.

Faster Turnaround with Item Transport Robots

-

Minimize Delays & Downtime

Enable first-in-first-out sample processing by reducing the wait time for batch completion.

-

Connect Isolated Process Stages

Bridge the travel gaps between lab stations for seamless and timely specimen transition through workflows.

-

Minimize Interruptions

Reduce disruptions caused by constant trips between departments, allowing staff to concentrate consistently.

Workflow Success with Supplies by Autonomous Delivery Robots

-

Improve Data Integrity

Integrate the C2 with existing LIMS for improved chain-of-custody control and traceable sample handling.

-

Boost Lab Agility & Responsiveness

Enable rapid reconfiguration of lab workflows and processes for faster adaptation to changing priorities

-

Achieve Rapid Automation ROI & Scale Affordably

Avoid high capital expenditures with a cost-effective entry point into lab automation – immediate deployment, instant integration, and achievable ROI in less than half a year.

Model C2 Internal Item Delivery

Lab Delivery Use Cases

Take your Life Science workflows to the next level with intelligent robotic automation.

Tell us your challenges, and we’ll show you how our solutions can help.

Autonomous Supply Delivery Robots

in Healthcare

Industry Challenges

The Strain of Inefficient Delivery on Nursing Staff

A critical staffing shortage & inefficient material retrieval practices force nurses to prioritize tedious logistical tasks over critical patient care.

5 miles

distance walked per shift

60 min

spent on just material transport

22 %

annual staff turnover rate

100 k

current shortage of staff

The Model C2 Effect

Autonomous Supply Delivery for Internal Hospital Logistics

Autonomous Supply Delivery that Powers Staff Efficiency

-

Reduce Physical Strain

Limit time spent on repetitive delivery errands to increase job satisfaction and decrease burnout.

-

Enhance Nurse Satisfaction:

Automate supply runs to get time back for direct patient care to provide better care and improving patient satisfaction.

-

Streamline Shift Change

Deliver patient records and essentials between shift handoffs to improve communication and reduce wait times.

Robotic Delivery Streamlines Hospital Workflows

-

Optimize Bed Turnover

Accelerate room cleaning by delivering supplies for faster patient admissions and discharges.

-

Connect Isolated Process Stages

Bridge the travel gaps between lab stations for seamless and timely specimen transition through workflows.

-

Assist in Rapid Response

Dispatch emergency equipment whenever it’s needed to let staff provide quicker response and maintain preparedness.

Mobile Service Robots Put Patients at the Center of Care

-

Accelerate Treatment and Recovery

Ensure timely delivery of medications and other essentials for faster diagnosis, treatment, and quicker recovery.

-

Improve Information Flow

Send documentation and educational materials directly to patients, improving communication and understanding.

-

Achieve Rapid Automation ROI & Scale Affordably

Avoid high capital expenditures with a cost-effective entry to hospital automation – immediate deployment, instant integration, and achievable ROI in months, not years.

Model C2 Automated Delivery Robots

Applications of Robotics Delivery in Healthcare

Elevate your patient care workflows with autonomous supply delivery of medicine, meals, and care items.

Tell us your challenges, and we’ll show you how our solutions can help.

Autonomous Supply Delivery Robots

in Warehousing & Manufacturing

Gain a Competitive Edge

with Autonomous Warehouse Robots

Autonomous Supply Delivery to Boost Safety, Productivity & Potential

-

Promote Better Ergonomics

Improve workplace safety and reduce the injury risk from repetitive lifting and carrying.

-

Increase Throughput

Eliminate time wasted on manual material transportation and redirect focus to quality control & process optimization.

-

Foster Employee Growth

Create opportunities for employees to learn new technologies and take on more challenging responsibilities.

Delivery for Smarter Autonomous Supply & Material Handling

-

Increase Order Fulfillment Quality

Enhance order picking and delivery to eliminate bottlenecks and meet customer demands more efficiently.

-

Collect Data Insight

Gather data on material flow, delivery times, and bottlenecks to identify areas for improvement and optimize processes.

-

Optimize Space and Equipment Utilization

Reduce congestion and optimize floor space while making sure equipment is continuously supplied with materials.

The Ripple Effect of Autonomous Supply Delivery

- Lower Operational Expenses:

Reduce labor costs, minimize material waste &energy consumption for significant long-term cost savings and faster ROI.

- Increase Facility Agility

Gain competitive responsiveness by adapting quickly to changing market demands and customer needs.

- Automate with Less Upfront Investment :

Position your facility in innovation by embracing automation technology.

Model C2 Autonomous Mobile Robot

Autonomous Warehouse Robots Move Your Facility Forward

Transform Your Warehouse with Affordable and Rapid ROI Automation Solutions

Contact Us to Request a Demo:

Autonomous Supply Delivery Robots

in Education

Transform the Learning Experience

with Intelligent Automation

Free Up Educators’ Time with Transport Robots

-

Reduce Administrative Burden

Free up lesson time by automating delivery of teaching materials and assignments.

-

Improve Classroom Management

Minimize disruptions and maximize instruction time with autonomous distribution and collection of assignments.

-

Foster Employee Growth

Create opportunities for employees to learn new technologies and take on more challenging responsibilities.

Spark Curiosity with Autonomous Supply Delivery in Action

-

Promote Student Engagement

Create an interactive learning environment by sparking curiosity about robotics/automation.

-

Foster Innovation

Encourage students to explore robotics problem-solving with student-led projects and initiatives.

-

Prepare for the Future Workforce

Expose students to real-world applications of robotics and automation in various industries.

Enhance Campus Efficiency with Autonomous Supply Delivery by a Mobile Robot Fleet

-

Optimize Resource Allocation

Improve the efficiency of campus operations and reduce waste by automating deliveries with less time, energy, and materials.

-

Enhance Sustainability Efforts

Reduce the environmental footprint and support campus commitment to sustainability by using energy-efficient autonomous delivery carts.

-

Create a Connected Campus

Integrate C2 with existing campus systems to improve communication and data flow.

Supply Delivery Applications with Transport Robots

Let’s create a customized autonomous delivery solution for your campus.

Contact us to get started:

Autonomous Supply Delivery Robots

in Hospitality

Model C2 & R2 Robot Applications

Retail, Hospitality, Grocery

Retail and grocery environments have been impacted by labor shortages and rising turnover, simultaneously facing ongoing pressure to differentiate among competitors and win over shoppers. Quasi robots provide solutions for efficient management of logistics and inventory, resulting in better customer service, cleanliness guidelines, and stocking measures.

Autonomous Supply Delivery in Restock Management

Model C2:

Transports pre-loaded items between designated warehouse or store locations based on human instruction, maintaining efficient stock flow.

Model R2:

Picks items from storage and places them onto transport for delivery. Receives and unloads new shipments, distributing items among specified storage locations.

Model C2 + Model R2:

Collaborate to streamline inventory management. R2 handles picking and placing tasks, while C2 ensures swift transport between locations. This reduces reliance on manual labor and optimizes stock organization.

Returns Processing with Autonomous Supply Delivery

Model C2:

Collects pre-sorted returns from designated drop-off points or collection bins, transporting them to a central returns processing area.

Model R2:

Sorts returned items based on condition, category, etc., and routes them to the appropriate locations (restocking, refurbishment, disposal).

Model C2 + Model R2:

Automate returns processing. R2 efficiently sorts returns, while C2 expedites their transport. This frees up staff time and streamlines the returns workflow.

Streamline Guest Luggage Handling

Model C2:

Autonomously transports guest luggage to and from rooms, enhancing guest experience and reducing staff workload.

Model R2:

Handles check-in/out kiosk interactions, verifying guest identity and assigning luggage to the appropriate C2 unit.

Model C2 + Model R2:

R2 manages guest interactions and luggage assignment, while C2 focuses on efficient transport, creating a seamless, high-tech experience for guests.

Model C2 & R2 Robot Applications

Other Industries

At Quasi, we’ve carefully selected our initial industries of focus based on our extensive prior team experience. Yet our overall vision remains more broad: to introduce autonomous supply delivery robotics to every sector of the market. We believe that the applications for our solutions exist across the board, in every industry, in every company, in every home even.

Homeland Security

While working to ensure the safety of our nation, officers and employees of the DHS are often exposed to dangerous situations and environments. By integrating autonomous supply delivery by Model C2 and R2 into their operations, exposure risk can be mitigated and tasks performed in unsafe environments can be reliably automated without threat to human team-members.

Safe Handling of Hazardous Materials

Model C2:

Autonomous supply & equipment delivery to and from contaminated areas, minimizing human exposure.

Model R2:

Manipulates hazardous materials within the contaminated zone, performing tasks like sampling, sorting, or basic testing.

Model C2 + Model R2:

R2 handles hazardous materials directly, preparing them for transport. C2 then safely moves the materials to designated areas for further analysis or disposal, optimizing safety and efficiency.

Law Enforcement

While working to ensure the safety of our nation, officers and employees of the DHS are often exposed to dangerous situations and environments. By integrating C2 and R2 into their operations, exposure risk can be mitigated and tasks performed in unsafe environments can be reliably automated without threat to human team-members.

Streamline Evidence Retrieval

Model C2:

Autonomously transports requested evidence from secure storage to authorized personnel.

Model R2:

Identifies and retrieves specific pieces of evidence within the storage area based on digital requests.

Model C2 + Model R2:

R2 locates and places evidence onto C2, which then delivers it directly to the requester, eliminating delays and minimizing security risks.